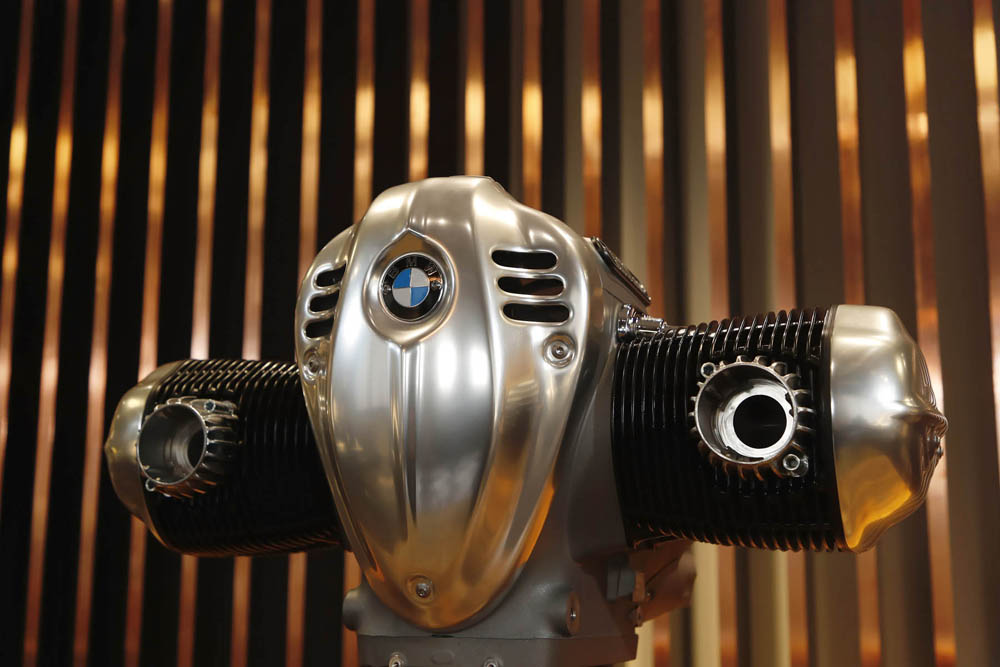

MOBILITY/TECHNICS: The „Big Boxer“ of the R 18 is also a feast for the eyes from the aesthetic side.

It is reminiscent of an aircraft engine, but made for the R 18. I am thrilled!

Munich. Motorcycling in its most original form: Feeling instead of thinking, technology not as self-dramatisation, but as a space for fantasy and great emotion instead of sober observation and factual calculation. With this message, the BMW Motorrad Concept R 18 made its debut at the Concorso d’Eleganza Villa d’Este in May 2019 as an expressive return to the core of the BMW Motorrad brand: the boxer engine.

Like no other current BMW motorbike before it, the Concept R 18 transferred the essence of famous BMW Motorrad classics into the present day, particularly in terms of form language, and at the same time gave a preview of a series-production motorbike that will enrich the BMW Motorrad Heritage experience world in the near future: the BMW R 18.

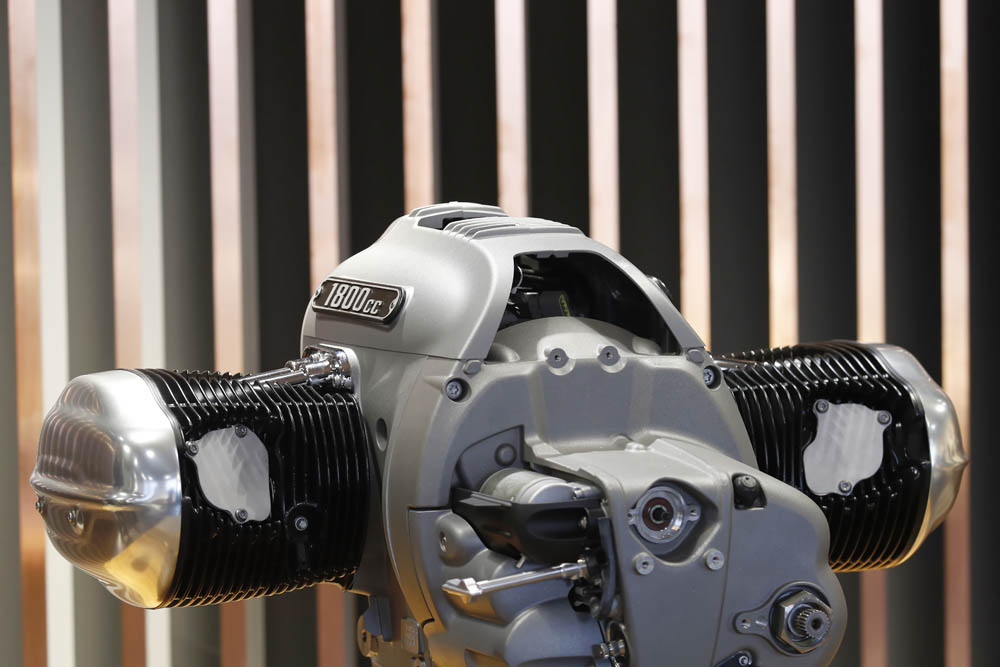

The largest two-cylinder boxer engine of all time.

At the heart of the new BMW R 18 is a completely newly developed two-cylinder boxer engine, the „Big Boxer“, as it has so far played the central role not only in the two BMW Motorrad Concepts – the Concept R 18 and the Concept R 18 /2 – but also in the custom bikes supported by BMW Motorrad, „The Departed“ by ZON and „Birdcage“ by Revival Cycles. Now BMW Motorrad is presenting this new, characterful engine in detail.

Not only with its impressive external appearance, but also from a technical point of view, the new „Big Boxer“ follows on from the traditional boxer engines that were synonymous with the motorbikes from Munich and Berlin-Spandau respectively for around 70 years from the start of BMW Motorrad production in 1923 until the appearance of the air/oil-cooled successor: clearly designed engines constructed with the best reliability and ease of maintenance in mind, with logically arranged but nevertheless powerful technology.

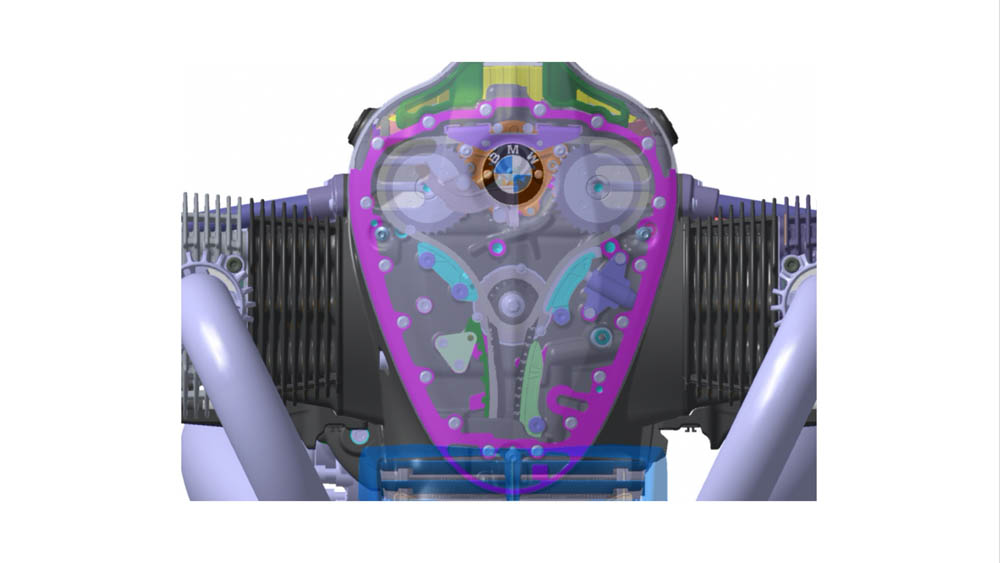

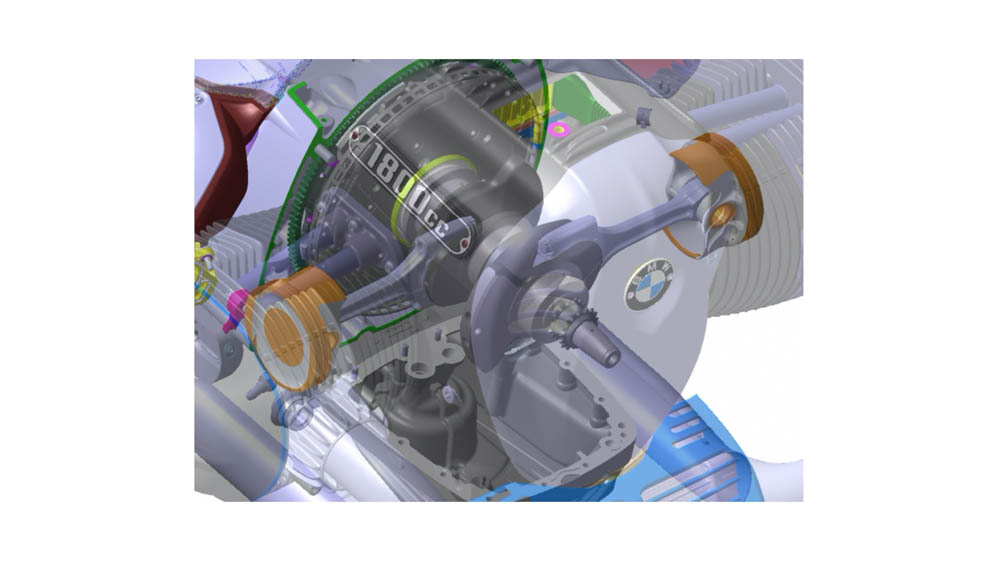

With an ohv valve train and separate engine and gearbox housing, the new „Big Boxer“ also bears the design features that already distinguished the first BMW Motorrad boxer engine, at that time still with side-controlled valves. The largest two-cylinder boxer engine ever used in motorbike series production has a displacement of 1 802 cm3, resulting from a 107.1 mm bore and 100 mm stroke. Engine output is 67 kW (91 hp) at 4 750 min-1. The maximum torque of 158 Nm is already available at 3 000 min-1. More than 150 Nm are available from 2 000 to 4 000 min-1. This means enormous pulling power and – in conjunction with a generously dimensioned flywheel mass – also exemplary smoothness. These are the advantages of this power and torque presentation that are so important in driving. Maximum speed is 5 750/min-1, idle speed is 950/min-1. Air/oil cooling, vertically split engine housing and triple plain bearing crankshaft drive.

The new „Big Boxer“ is air/oil cooled, has large-area finned cylinders and cylinder heads and weighs 110.8 kg including gearbox and intake system. It has a vertically split aluminium engine housing.

In contrast to the classic air-cooled two-valve boxer engines from BMW Motorrad, however, the crankshaft of the „Big Boxer“, forged from heat-treatable steel, has an additional main bearing in the middle, which became necessary due to the enormous cylinder volume in order to prevent unwanted bending vibrations of the crankshaft.

Like the crankshaft, the two connecting rods with I-shaft are mounted on plain bearings and are also forged from heat-treatable steel. They accommodate pistons cast from aluminium with two compression rings and an oil scraper ring. The running surface of the light-alloy cylinders is coated with NiCaSil.

Lubrication and cooling oil are supplied by a wet sump lubrication system with a two-stage oil pump driven by the crankshaft via a sleeve chain.

Classic ohv valve train with two camshafts as on the legendary R 5 up to the R 51/2 paired with modern four-valve technology and dual ignition.

Although the new „Big Boxer“ relies on four valves, dual ignition, a modern combustion chamber architecture as well as intake manifold injection and the BMS-O engine management system for the best possible torque presentation as well as optimum consumption and emission values, it relies on the classic ohv design for the valve train as it was used by BMW Motorrad for around 70 years.

When developing the valve train for the „Big Boxer“, the BMW Motorrad engineers were inspired by a very special engine design in the history of BMW Motorrad – in keeping with the heritage concept: the two-cylinder boxer engine of the R 5/R 51 (1936 – 1941) or R 51/2 (1950 – 1951), the first BMW motorbike with a boxer engine after the Second World War. In contrast to the other ohv designs from BMW Motorrad, this engine, which is highly regarded by connoisseurs, has two camshafts driven by the crankshaft by means of a sleeve chain.

As with the historical model, the two camshafts are also arranged on the left and right above the crankshaft in the „Big Boxer“. The advantages of this „twin-cam boxer“ are shorter pushrods. This is accompanied by reduced moving masses, reduced deflections and lower linear expansions. An overall stiffer valve train with improved timing precision and higher speed stability is the consequence of this more complex design.

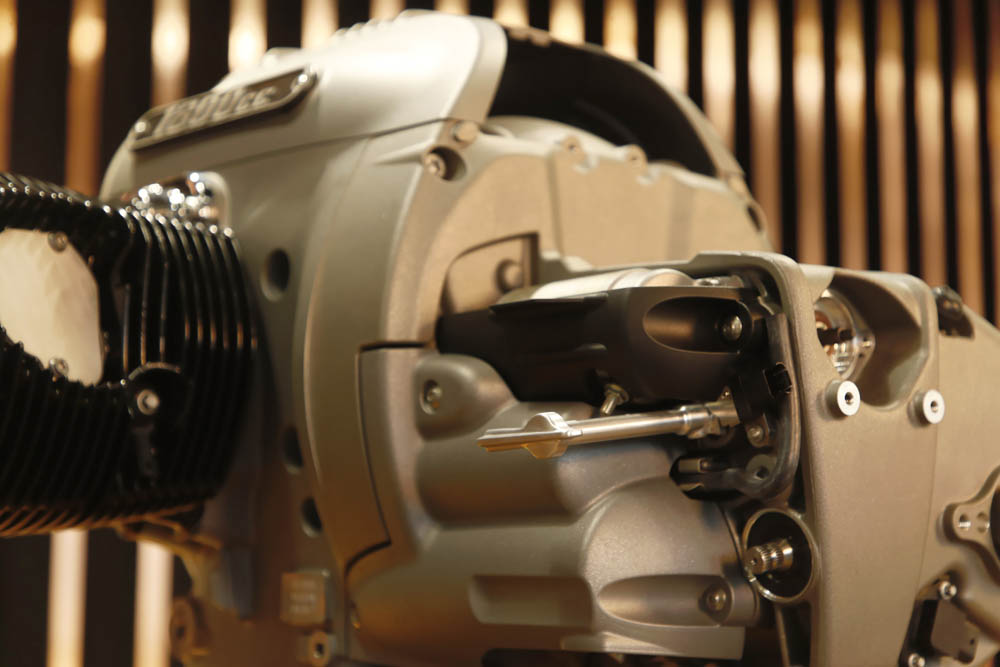

Fork rocker arm and valve lash adjustment manually adjustable via adjusting screws according to the traditional BMW boxer model.

In traditional BMW Motorrad boxer design, the two pushrods actuate one pushrod per cylinder side for the intake and one for the exhaust side, guided in a sealed pushrod tube on the top of the cylinders. The two intake and exhaust valves in the cylinder head are operated in pairs by fork rocker arms.

Contrary to today’s engine technology, however, the valve lash adjustment is not carried out via hydroelements, but – as was common for decades on most classic air-cooled BMW two-valve boxers – via one adjusting screw with lock nut per valve. As was once the case with the classic two-valve boxers, the adjustment of the valve clearance (0.2 – 0.3 mm) is thus also possible in a very short time on the „big boxer“ of the R 18. The steel valves measure 41.2 mm in diameter on the inlet side and 35 mm on the outlet side. The valve angle is 21 degrees on the inlet side and 24 degrees on the outlet side.

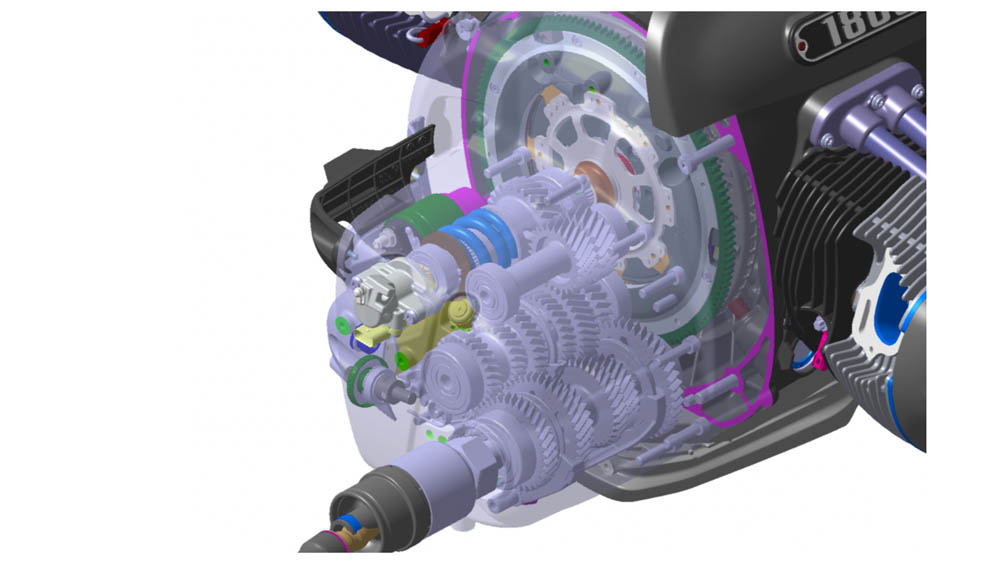

Claw-shifted six-speed gearbox and self-reinforcing single-disc dry clutch with anti-hopping function.

As has been customary for decades with the vast majority of BMW Motorrad boxer engines (exception: vertical-flow, air/water-cooled boxer since 2012), a single-plate dry clutch transmits the torque generated by the engine to the transmission. For the first time, it is designed as a self-reinforcing anti-hopping clutch and thus eliminates the undesirable stamping of the rear wheel caused by the engine drag torque during hard downshifts.

The six-speed, dog-shifted gearbox is housed in a two-piece aluminium casing and is designed as a four-shaft gearbox with pairs of helical gears. The gearbox input shaft with a bellcrank damper drives the two gearbox shafts with the gear pairs.

An output shaft is arranged to bridge the distance and reverse the direction of rotation. A reverse gear is available as an optional extra. This is driven by a primary reduction gear and an electric motor and can be shifted manually.

Open-running secondary drive based on the classic model.

As on all BMW motorbikes with a boxer engine, the torque transmission from the gearbox to the rear wheel on the R 18 is also via a cardan shaft drive with universal joint, shaft and rear axle drive with bevel and ring gear. As was customary for BMW Motorrad up to and including the 1955 model year, the cardan shaft and universal joint are bright nickel-plated and run open in the spirit of fascinating classic motorbike technology. A so-called tripoid joint is used on the transmission side for length compensation.

BRAND: Bayerische Motoren Werke Aktiengesellschaft

virtualdesignmagazine Michael Hiller